Laser depaneling machines from LPKF stand for quality made in Germany and constant technological advancements for high-quality depaneling results with a wide variety of materials.

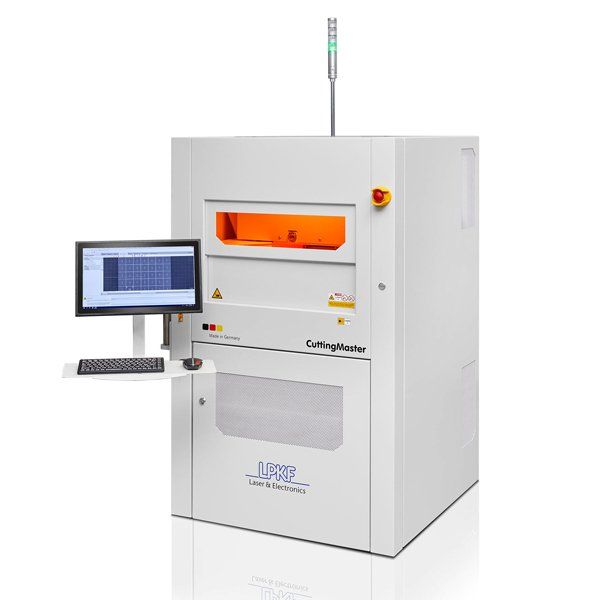

CuttingMaster series

The CuttingMaster series convinces with highest precision due to its equipment with linear drives and a large working area. equipped with different laser sources and pulse durations in the nanosecond and picosecond range, enabling the processing of different materials: whether Flex, Rigid-Flex or FR4 (all strengths) and of course LTCC, Al2O3, PTFE, LCP.

Our customers are already convinced -

You too?

See laser depaneling for yourself during a demo - even directly on your own products!

Our systems for cleanly separated PCBs

CuttingMaster 2000

The CuttingMaster 2000-series combines performance and efficiency with a result that speaks for itself. Thanks to its compact construction, the 2000-series saves valuable space in the production and is designed for high throughput and best cutting quality.

- Four levels of laser power: 22W, 27W, 32W und 40W

- Two types of laser: UV-Laser, green Laser

- Max. working space: 350mm x 350mm x 11mm

- Positioning accuracy: ± 25µm

- Laser beam diameter: < 20µm

CuttingMaster 3000

The CuttingMaster 3000 series is equipped with different laser sources and pulse durations in the nanosecond and picosecond range, enabling the processing of different materials: whether Flex, Rigid-Flex or FR4 (all strengths) and of course LTCC, Al2O3, PTFE, LCP.

Furthermore, the 3000-series can also be used for drilling applications.

- Three levels of laser power: 27W, 36W und 65W

- Two types of laser: UV-Laser, green Laser

- Max. working space: 500mm x 350mm x 11mm

- Positioning accuracy: ± 20µm

- Laser beam diameter: < 20µm